SLB continues to win new long-cycle contract awards that align with SLB’s core strengths, particularly in the international and offshore basins.

SLB Wins $1 Billion Award Over Two Years for Exploration and Development in Mexico

In Mexico, through its reference agreement process, our main customer in Mexico awarded SLB contracts with a total value of approximately $1 billion over the next two years for land and shallow-water exploration and development. SLB will provide drilling technology and completion solutions to execute both conventional and highly complex wells, including high-pressure and high-temperature work.

Qatargas Awards SLB a Five-Year Contract for Cameron Systems

In Qatar, Qatargas awarded SLB a five-year exclusive contract with an optional five-year extension for the provision of unitized Cameron wellhead and tree systems. The equipment will be installed in 50 offshore and five onshore wells in the North Field South project and will incorporate MRD recessed-bore metal-to-metal seals and CANH rough casing metal-to-metal seals. The onshore portion of the project includes CO2 injection and wastewater wells. The first delivery of the equipment is expected in the third quarter of 2023.

OneSubsea Wins Sixth Consecutive Award from Petrobras for Búzios Development

In Brazil, Petrobras awarded a contract to OneSubsea to supply critical subsea equipment to assist in the development of the Búzios pre-salt field in the country's prolific Santos Basin. It was the sixth consecutive contract covering the supply of subsea trees signed between the two parties. SLB will supply 15 subsea trees and electrohydraulic distribution units to serve the Búzios-11 project, set to enter production in 2027 via the P-83 floating production, storage, and offloading vessel. The contract work scope also includes installation, commissioning, and associated maintenance services.

SLB is deploying digital technology at scale, enabling customers to track and access their data, leverage insights to elevate their performance, and embrace new AI-enabled autonomous operations.

Petrobras Awards SLB a Five-Year Contract for Digital Technologies

In Brazil, SLB was awarded a five-year contract by Petrobras for an enterprise-wide deployment of its Delfi digital platform. The contract scope facilitates Petrobras' digital transformation from exploration, development, and production operations, including moving subsurface workflows to the cloud to significantly accelerate decision making. The award represents one of Petrobras' largest investments in cloud-based technologies.

SLB and Cognite to Deliver Unified Enterprise Data Platform in India

In India, Cairn Oil & Gas, Vedanta Limited selected SLB and Cognite to deploy an industrial DataOps platform at the enterprise level. The project scope includes implementation of a consolidated and unified data enterprise platform for reservoir management in the Rajasthan basin, with the aim of enhancing efficiency, leveraging data science and analytics, and enabling the development of novel applications to optimize reservoir and production workflows. Vedanta plans to leverage the Cognite Data Fusion® platform as well as SLB domain-driven workflows and oil and gas expertise. The three-year strategic project will establish a reusable, flexible data foundation and enable data and domain users to obtain value from actionable insights.

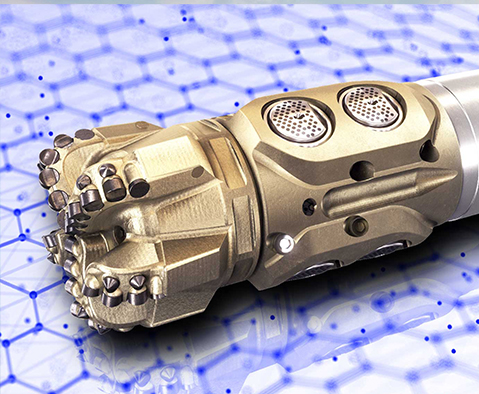

Neuro Autonomous Solutions Optimize Drilling Performance in Kuwait

In Kuwait, Kuwait Oil Company (KOC) implemented Neuro autonomous solutions, which included the autonomous downhole control system, DrillOps Automate, DD Advisor coupled with well construction rig equipment, the AxeBlade ridged diamond element bit, and the PowerDrive Orbit G2 rotary steerable system. Optimization through autonomous directional drilling capabilities delivered a 90% increase in rate of penetration and a 37% increase in steering effectiveness, saving over $500,000 and eight rig days compared to the authorization for expenditure. Neuro solutions are redefining what can be achieved when state-of-the-art software is coupled with intelligent hardware and work processes that eliminate manual operations. The successful adoption of these technologies not only improved KOC's drilling performance and efficiency but also minimized operational costs and drilling durations, directly impacting their profitability.