First-Quarter 2024

$8.71b

Revenue of $8.71 billion increased 13% year on year

$0.75

EPS, excluding charges & credits, of $0.75 increased 19% year on year

GAAP EPS was $0.74

GAAP EPS was $0.74

$2.06b

Adjusted EBITDA of $2.06 billion increased 15% year on year

Net income attributable to SLB was $1.07 billion

Net income attributable to SLB was $1.07 billion

$0.33b

Cash flow from operations was $0.33 billion

Please refer to the Form 8-K filed on April 19, 2024 for a reconciliation of non-GAAP measures to their most comparable GAAP measures

SLB Announces Agreement to Acquire ChampionX in an All-Stock Transaction

We are committed to being at the forefront of the global shift toward more sustainable energy production.

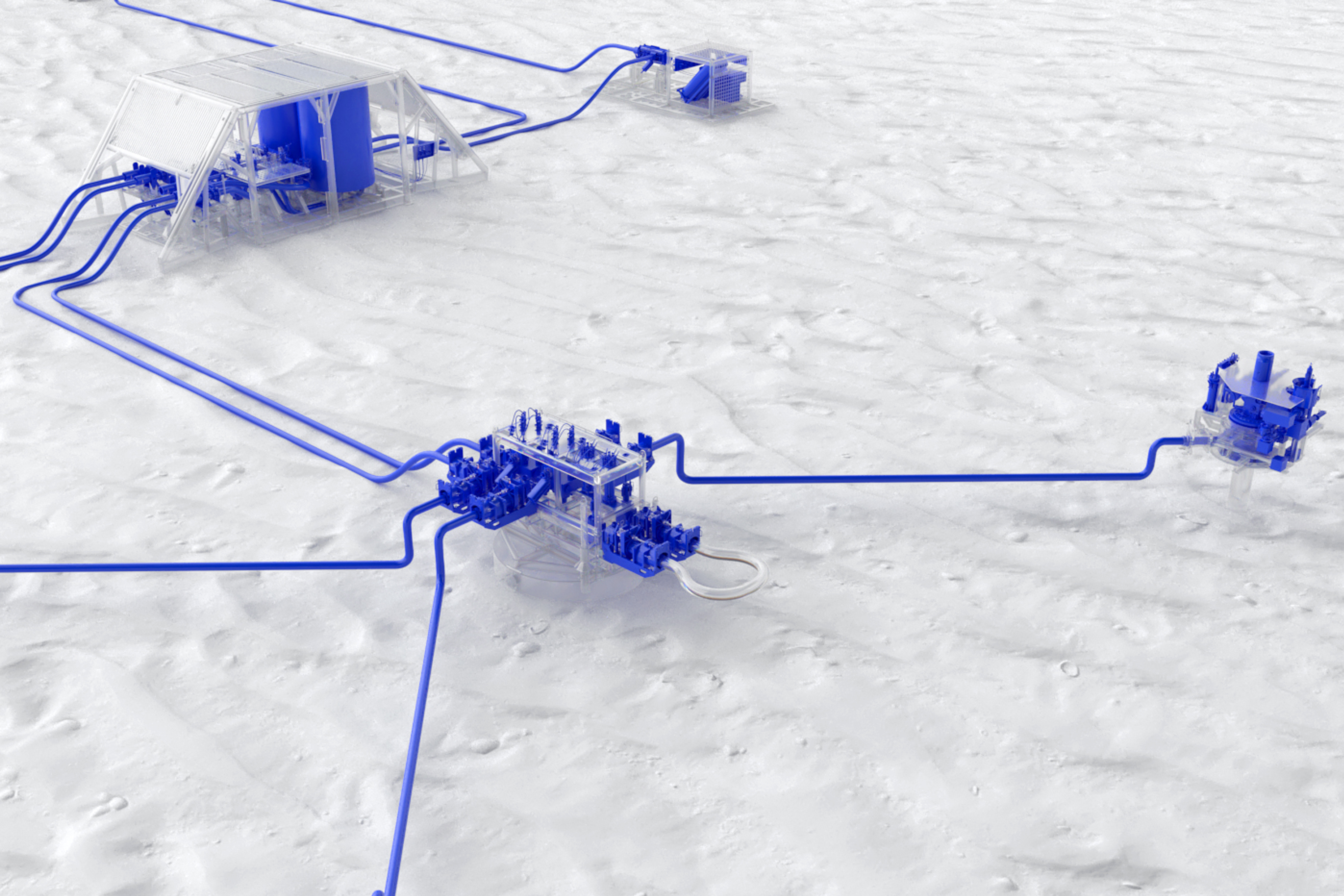

SLB, Aker Solutions, and Subsea7 Announce Closing of OneSubsea Joint Venture

Barclays CEO Energy-Power Conference

The Power of the Core and Digital Driving Growth—Today and Tomorrow

September 6, 2023

New York, NY

New York, NY

We are committed to being at the forefront of the global shift toward more sustainable energy production.

J.P. Morgan Energy, Power and Renewables Conference

Offshore Breadth, Resilience, and Durability—and SLB's Unparalleled Offering

June 21, 2023

New York, NY

New York, NY

19 April 2024 | 9:30 AM EDT

02 April 2024 | 9:00 AM EDT

18 March 2024